On the path to net-zero emissions, have you considered the impact of pump systems on energy efficiency? Sealless magnetic drive pumps, as leak-free and high-performance transport equipment, are quietly becoming a crucial driver in industrial environmental upgrades, allowing businesses to achieve sustainable development while reducing operational costs.

Kung Hai Enterprise has been deeply rooted in the pump industry for over 40 years, actively assisting companies in building energy-efficient pump systems. How can magnetic drive pumps become an energy-saving tool for your business? Let's explore the technology and its potential applications.

A Green Future Driven by Magnetic Force

Sealless magnetic drive pumps are not only suitable for traditional industries but also play a crucial role in emerging green energy sectors. From the clean production of hydrogen energy to the efficient operation of wind power, from the safe treatment of wastewater and exhaust gases to the sustainable recycling of bioenergy, sealless magnetic drive pumps have achieved a perfect combination of "environmental protection" and "efficiency." For a deeper understanding of the applications and advantages of sealless magnetic drive pumps in various industries, you can refer to our previously published series of articles:

[ Hydrogen Energy ]

Overview: In the hydrogen electrolysis process, sealless magnetic drive pumps are required to transport the electrolyte to the electrolyzer. Since electrolytes are often chemically corrosive, leakage during transport must be prevented. In this case, sealless magnetic drive pumps made of corrosion-resistant materials are essential to ensure the continuity and stable operation of the hydrogen production process.

[ Wind Energy ]

Overview: In wind power generation systems, sealless magnetic drive pumps can be used to transport coolants and lubricating oils to the generator units, maintaining the generators within the optimal temperature range for continuous and stable operation.

[ Wastewater & Exhaust Gas Treatment ]

Overview: Scrubbing towers require pumps to transport scrubbing liquids. The scrubbing liquid is pumped to the top of the tower and then sprayed downwards to purify waste gases. After purification, part of the liquid is pumped back into the scrubbing tower for continuous recycling, while the remainder is discharged to wastewater treatment plants. Since the scrubbing liquid is corrosive, corrosion-resistant pumps are essential. Sealless magnetic drive pumps are particularly suitable for this application, effectively preventing dangerous leaks of chemical liquids.

[ Biofuel ]

Overview: In the process of converting biomass feedstock into liquid fuel, stainless steel magnetic drive pumps are responsible for transporting biodiesel or bioethanol. These pumps effectively handle solid particles and impurities in biofuels, while the stainless steel material ensures the purity of the product.

[ Hydrogen Fuel Cells ]

Overview: In fuel cell equipment, well-designed cooling and heat recovery systems are necessary. The cooling system requires circulating coolant to remove waste heat. For coolant circulation pumps, sealless magnetic drive pumps are suitable as they can prevent coolant leakage and subsequent losses.

Key Features of Sealless Magnetic Drive Pumps

For an understanding of how sealless magnetic drive pumps operate, refer to this article: What's a Sealless Magnetic Drive Pump & How Does It Work?

After gaining a basic understanding of how magnetic pumps work, let's analyze the three main features of sealless magnetic drive pumps and how they can help your industry achieve energy-saving and carbon reduction goals.

- Leak-free design:

Without mechanical seals, magnetic drive pumps can eliminate the risk of fluid leakage, reducing environmental pollution from chemicals while protecting operator safety. This significantly reduces the environmental burden in chemical processes, adhering to green technology principles. - High energy efficiency:

Our sealless magnetic drive pumps offer special energy-saving designs, which can significantly save energy consumption and electricity bills. By correctly configuring and using magnetic pumps, these pumps can greatly reduce energy consumption, improve production efficiency, and meet corporate energy efficiency standards. - Durability and low maintenance requirements:

The sealless design avoids mechanical wear, significantly reducing maintenance frequency and further extending the pump's lifespan. With fewer part replacements needed, this reduces the product’s carbon footprint, minimizing resource waste from equipment repairs and replacements.

How Sealless Magnetic Drive Pumps Help Companies Achieve Net Zero Goals

Improving equipment efficiency is one of the key strategies in achieving emission reduction targets. The design of sealless magnetic drive pumps allows for highly efficient operation and significant carbon footprint reduction, making them a powerful energy-saving tool for businesses. Sealless magnetic drive pumps are used in a wide range of applications. Beyond the aforementioned green industries, they also play a crucial role in promoting environmental protection in sectors such as chemical, semiconductor, and food and pharmaceutical industries. In terms of carbon reduction efforts in these industries, process improvements can incorporate energy-efficient equipment to enhance process efficiency. At the same time, adopting sealless magnetic drive pumps can meet the requirements for high-performance and pollution-free processes.

Additionally, as global organizations accelerate their efforts to achieve "Net Zero by 2050," the application of sealless magnetic drive pumps continues to expand. Companies adopting high-efficiency equipment not only contribute to meeting international energy management standards but also, in the long run, strike a balance between production efficiency and environmental benefits.

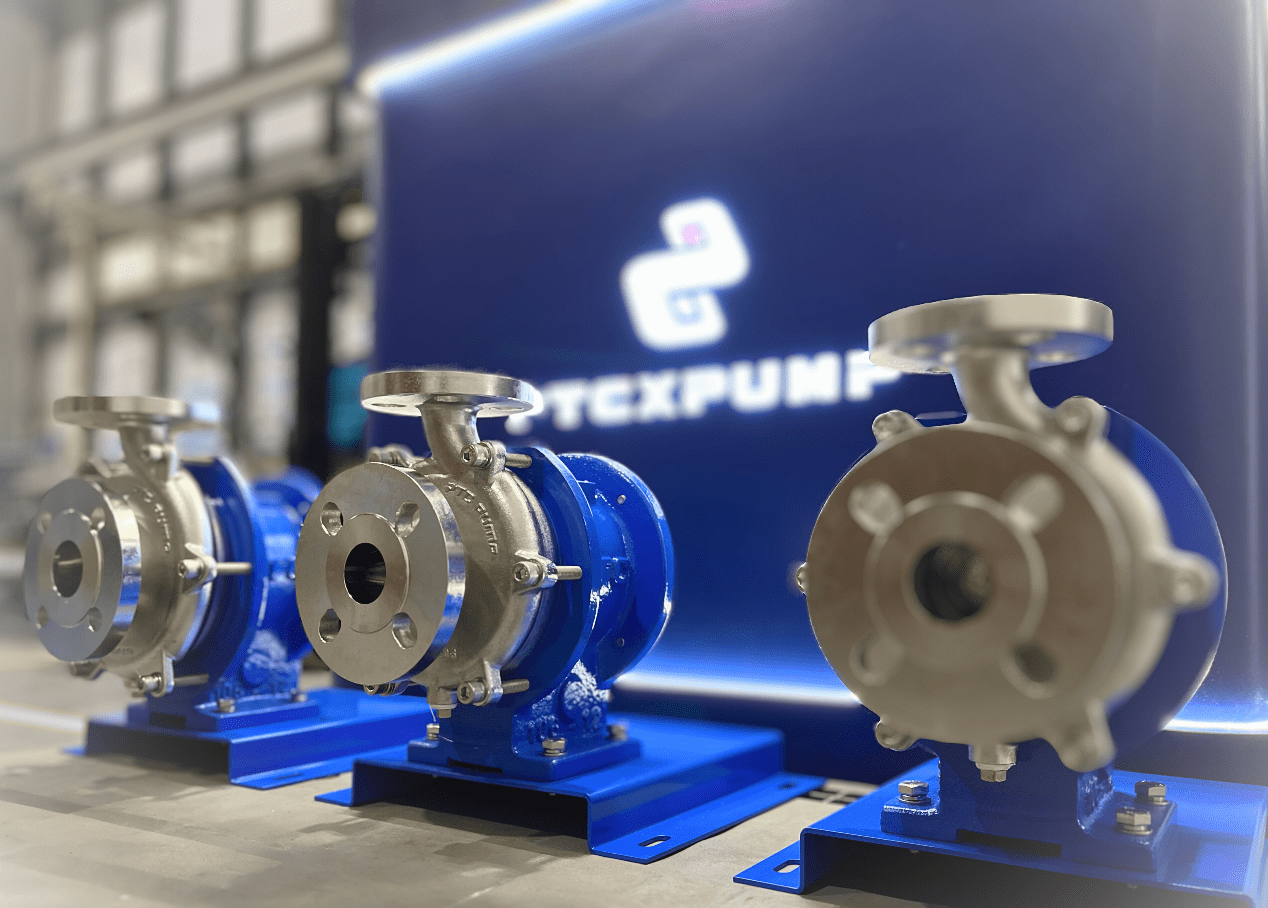

PTCXPUMP Metallic Magnetic Drive Pump

Highly efficient design with CE and ATEX certificates.

PTCXPUMP Thermoplastic Magnetic Drive Pump

Sealless structure, magnetic drive, no leakage concerns

Customized Energy-Saving Solutions: Kung Hai Responds to the Green Movement

As a leading brand in sealless magnetic drive pumps, PTCXPUMP offers not only standardized pumps but also customized energy-saving solutions tailored to the specific needs of our clients, creating the most suitable pump systems. In response to the global call for green transformation, Kung Hai provides comprehensive customized energy-saving solutions:

- System Optimization: Through a comprehensive assessment of the client's pump system, we provide recommendations for improving energy efficiency. These may include replacing outdated pumps, selecting appropriate pump models, and optimizing pump structure design.

- Energy-Saving Design: Our pumps utilize specialized energy-efficient design that can significantly reduce energy consumption and electricity costs.

- Premium Materials: We use materials such as GFR-PP, CFR-ETFE, stainless steel, and special alloys. These materials effectively resist corrosion from chemical fluids and maintain stable operation over extended periods. This approach reduces maintenance time and costs, thereby improving production efficiency.

- Interchangeable Parts: Key parts in pumps of different sizes are designed with a modular, streamlined approach. This not only enhances component interchangeability but also brings multiple environmental benefits:

- Reduction in raw material usage

- Decrease in waste generation

- Significant lowering of spare parts procurement costs

- Simplification of maintenance processes, controlling operational costs

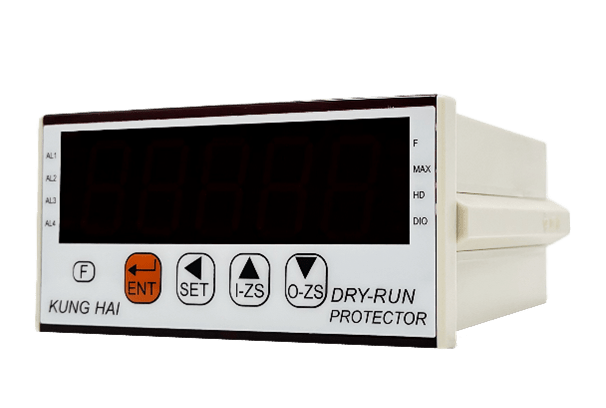

- Operational Monitoring: We install dry-run protectors to monitor the pump system's status. When abnormal current or power is detected, it automatically protects the pump from running dry, preventing damage to internal components.

Dry Run Protector

Ensure smooth and stable pump operation.

Through these innovative measures, not only can you reduce the environmental impact, but you can also demonstrate your corporate social responsibility while driving carbon reduction efforts. This, in turn, enhances your competitiveness in the international market.

PTCXPUMP's sealless magnetic drive pumps are available in a variety of specifications, head, and flow rates to meet the specific requirements of various application fields.

If your industry is moving towards green technology development and you want to learn more about the energy-saving design of PTCXPUMP sealless magnetic drive pumps, click the button below now. Kung Hai's expert team will provide you with consultation services as soon as possible!

▌Read More: 10 Tips on Energy Saving in Pumping Systems