In food and beverage manufacturing processes, strict hygiene control is essential to ensure food safety and quality. High-temperature sterilization is a commonly used method in food factories to eliminate microorganisms in products or equipment through high temperatures to prevent food contamination. In this high-temperature sterilization process, the temperature and time need to be precisely controlled, along with a stable hot water delivery system. Sealless magnetic drive pumps have gained positive recognition in the food manufacturing industry due to their leak-free, high-temperature resistance and low maintenance.

In this article, we will introduce the three main types of food high-temperature sterilization and how they operate, and discuss how to choose the suitable pump for food sterilization equipment, as well as some precautions.

Types and Operating Principles of Food High-Temperature Sterilization

1. Steam Sterilization / Retort Sterilization

Steam sterilization is suitable for various pipelines and equipment, using the high temperature of saturated steam to destroy bacterial spores, making it ideal for canned foods and other long-term preservation products. However, steam sterilization equipment consumes a lot of energy and is not environmentally friendly.

- How it works: Steam at about 121°C is introduced into the pipeline or equipment, it needs to be maintained at high temperature and high pressure for a period of time to achieve complete sterilization.

- Advantages: It can kill most bacteria, enabling long-term product preservation.

- Disadvantages: High energy consumption, which may lead to increased operating costs.

2. Hot Water Sterilization

Hot Water Sterilization is used for cleaning equipment, piping, and for sterilizing food. Common sterilization methods include Pasteurization, Hot Water Shower Spray Sterilizer and Water Immersion Retort.

- How it works:

Cleaning equipment and pipelines: Using 85°C~95°C hot water, transported to the sterilization equipment through a circulating hot water pump to clean the equipment and pipelines, and effectively remove residual microorganisms and impurities in a short time. For food factories, hot water sterilization provides significant assistance in equipment maintenance and daily cleaning. - Food Product Sterilization: The packaged food is placed in a closed water spray retort, and the high-temperature water sprays on the surface of the food packaging, so that the food is evenly heated and the sterilization efficiency is improved. It is common in canned or bottled beverage sterilization operations.

- Advantages: It can achieve uniform heating of food, and at the same time avoid the problem of deformation or rupture of product packaging due to high pressure; There is no problem of large amount of exhaust like steam sterilization.

- Disadvantages: The sterilization effect is not as good as steam sterilization.

3. UHT (Ultra-high-temperature)

Sterilizing the bacteria in a short period of time with extremely high temperature, which is suitable for the mass production of milk, juice, soy milk and other foods. For example, long life milk, it can be stored at room temperature for a long period after sterilization and aseptic packaging; while fresh milk cannot be sterilized to the same degree, so it must be refrigerated throughout the process. There are different sterilization standards for different food products.

- How it works: Beverages are treated at high temperatures for a few seconds and then sealed packaging.

- Advantages: Due to the fairly short heating time, the nutrition and flavor of the food can be preserved.

- Disadvantages: Not suitable for foods containing more solid particles.

The above introduces three common sterilization methods, which basically need to be decided according to the type of food and sterilization standards. If the sterilization is incomplete, what problems will occur?

Is Sterilization Always Safe? Beware of Food Poisoning

Incomplete sterilization, which means the sterilization process is not done to an adequate degree, can lead to serious food safety issues, including:

- Consumers may get food poisoning from eating spoiled food:

Residual microorganisms will breed and multiply in food, causing food spoilage, odor, discoloration, and even toxins. When spoiled food is consumed, it will cause health hazards and may lead to food poisoning, abdominal pain, vomiting, diarrhea and other symptoms, and in severe cases, sometimes even life-threatening conditions. - Reduce the shelf life of food:

Incompletely sterilized food will greatly shorten the shelf life and is easy to spoil in a short time. - Food waste:

Spoiled food must be destroyed and scrapped, resulting in a waste of materials and costs. On the other hand, the brand image of the company will be severely damaged if there are news reports. - Legal responsibility:

Incomplete commercial sterilization of food and failure to meet basic hygiene standards are illegal acts and may face relevant legal issues.

Causes of Incomplete Commercial Food Sterilization:

- Insufficient sterilization temperature or time: The sterilization process is stopped before the food reaches the standard value of sterilization.

- Equipment problems: The equipment in the sterilization system isn't kept clean when used or lacks proper maintenance, leading to contamination and failure to meet specified sterilization conditions.

- Incomplete product sealing during packaging: Microorganisms may enter food through gaps from the outside.

For the food industry, food safety is the priority. In order to ensure the integrity of the sterilization process, in addition to choosing the appropriate sterilization method, we also need to pay attention to the reliability of the equipment system, as well as cleaning and maintenance issues, which directly affect whether food can meet hygienic standards or not.

Pump Requirements in Food High-Temperature Sterilization Equipment

Why Should Food Sterilization Equipment Use Sealless Magnetic Drive Pumps?

In the hot water sterilization process, the pump used in the process from hot water transportation to the cooling system is one of the important equipment for meeting sterilization standards. Here are the specific applications of stainless steel magnetic drive pumps in equipment systems:

- Transfer hot water to sterilization equipment:

The stainless steel magnetic drive pump delivers hot water to the retort sterilizer, providing a stable flow and head that helps maintain the sterilization process's precise requirements. - Cleaning equipment and piping:

After each production batch, the parts of the storage tank and pipeline that come into contact with food should be cleaned with hot water or chemicals to keep the production line clean. Stainless steel magnetic drive pumps are used to transfer the cleaning solution to the CIP (Clean-In-Place) system. Stainless steel material has excellent corrosion resistance, which allows for transferring various acid and alkali cleaning solutions. The sealless design ensures no leakage, which can fully prevent the process from contamination. - Cooling water recycling system:

When the sterilization is completed, the used hot water will be cooled down through the heat exchanger, and the sealless magnetic drive pump will recycle it to the external cooling water system for reuse.

Key Factors in Selecting Food Sterilization Pumps

According to the above three process stages, when selecting pumps for food sterilization equipment, it is recommended to consider and evaluate these aspects:

- Heat Resistance and Stability:

The sterilization processes involve high temperatures, usually over 100°C, so the pumps used in the equipment must be able to withstand high temperatures. PTCXPUMP stainless steel magnetic drive pumps can operate at temperatures up to 280°C, with excellent stable performance even under long-term use. - No need for frequent maintenance:

Food storage tanks and piping generally need to be cleaned every day, demanding high equipment durability. Stainless steel magnetic drive pumps can be exempted from frequent maintenance, greatly reducing maintenance costs and downtime. - Ensure the purity of cooling water:

Sealless magnetic drive pumps use the magnetic coupling drive principles to form a completely sealed fluid chamber, which effectively prevents the cooling water from leaking or being contaminated and ensures its purity for subsequent recycling and reuse.

Choose the Right Equipment for Food Safety Control!

For the food manufacturing industry, the worst thing that can happen in the process is when improper equipment selection leads to substandard food hygiene and quality issues. Therefore, to make sure that food is safe to eat, it is important to select appropriate equipment and have complete sterilization procedures.

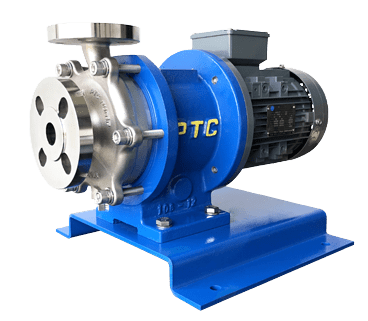

The quality of pumping equipment directly affects sterilization effect and production efficiency. PTCXPUMP metallic sealless magnetic drive pump features excellent heat resistance, no leakage, and maintenance-free characteristics, making it an ideal choice for food sterilization equipment in hot water delivery, equipment cleaning solution transfer, and cooling water recycling applications.

PTCXPUMP Metallic Magnetic Drive Pump

Highly efficient design with CE and ATEX certificates.

If you are planning to build or improve food sterilization equipment, please contact us.

Click the button below, and the Kung Hai expert team will provide consultation based on your application needs as soon as possible!