In our previous article "Top 5 Benefits of Using Metallic Magnetic Drive Pumps in Hydrogen Stations", we explored the advantages of hydrogen vehicles and the importance of hydrogen refueling stations. Today, we'll take a closer look at the core of hydrogen vehicles - fuel cells. How do fuel cells convert hydrogen into power? What makes them special in terms of environmental protection and efficiency?

By uncovering the answers to these questions, we'll provide a comprehensive understanding of how fuel cells lay the foundation for the future of hydrogen vehicles and identify the key equipment needed for a safe and efficient fuel cell production system.

What is a Fuel Cell?

A fuel cell is an energy conversion device that generates electricity through a chemical reaction between hydrogen (or other fuels) and oxygen. It directly converts chemical energy into electrical energy with an efficiency of over 60%.

The main difference between fuel cells and traditional batteries is that traditional batteries store energy internally and need replacement or recharging after use. Fuel cells, on the other hand, require a continuous supply of fuel (commonly hydrogen) and an oxidizer (commonly oxygen). As long as fuel and oxidizer are continuously supplied, fuel cells can continue to generate electricity as a power source for various equipment.

How do Fuel Cells Work?

The working principle of a fuel cell is actually the reverse reaction of water electrolysis. First, we need to understand what water electrolysis is.

Reaction of Water Electrolysis: When an electric current passes through water, it decomposes into hydrogen and oxygen.

💧Water + Electricity = Hydrogen + Oxygen

Reverse Reaction of Water Electrolysis: This is the opposite of the above formula, mixing hydrogen and oxygen. When hydrogen and oxygen are introduced into the two electrodes of a fuel cell, oxygen combines with hydrogen ions to form water. The electrons produced in this process create a current in the external circuit, thus generating electricity.

💭Hydrogen + Oxygen = Water + Electricity

From the above formulas and diagrams, we can see that the only byproduct of fuel cell power generation is water, which does not cause any environmental pollution. Traditional combustion methods produce harmful waste like carbon dioxide, leading to air pollution problems, which can be solved by replacing them with fuel cells. As the demand for reducing carbon emissions grows, the importance of fuel cell applications is also increasing.

Types of Fuel Cells

After understanding the concept of fuel cell power generation, it's important to note that there are many types of fuel cells, each designed for specific application needs. The most common types include Proton Exchange Membrane Fuel Cells (PEMFC), Alkaline Fuel Cells (AFC), Phosphoric Acid Fuel Cells (PAFC), Molten Carbonate Fuel Cells (MCFC), and Solid Oxide Fuel Cells (SOFC).

Proton Exchange Membrane Fuel Cells (PEMFC) are the most widely used power generation systems for hydrogen vehicles. Here's how it works.

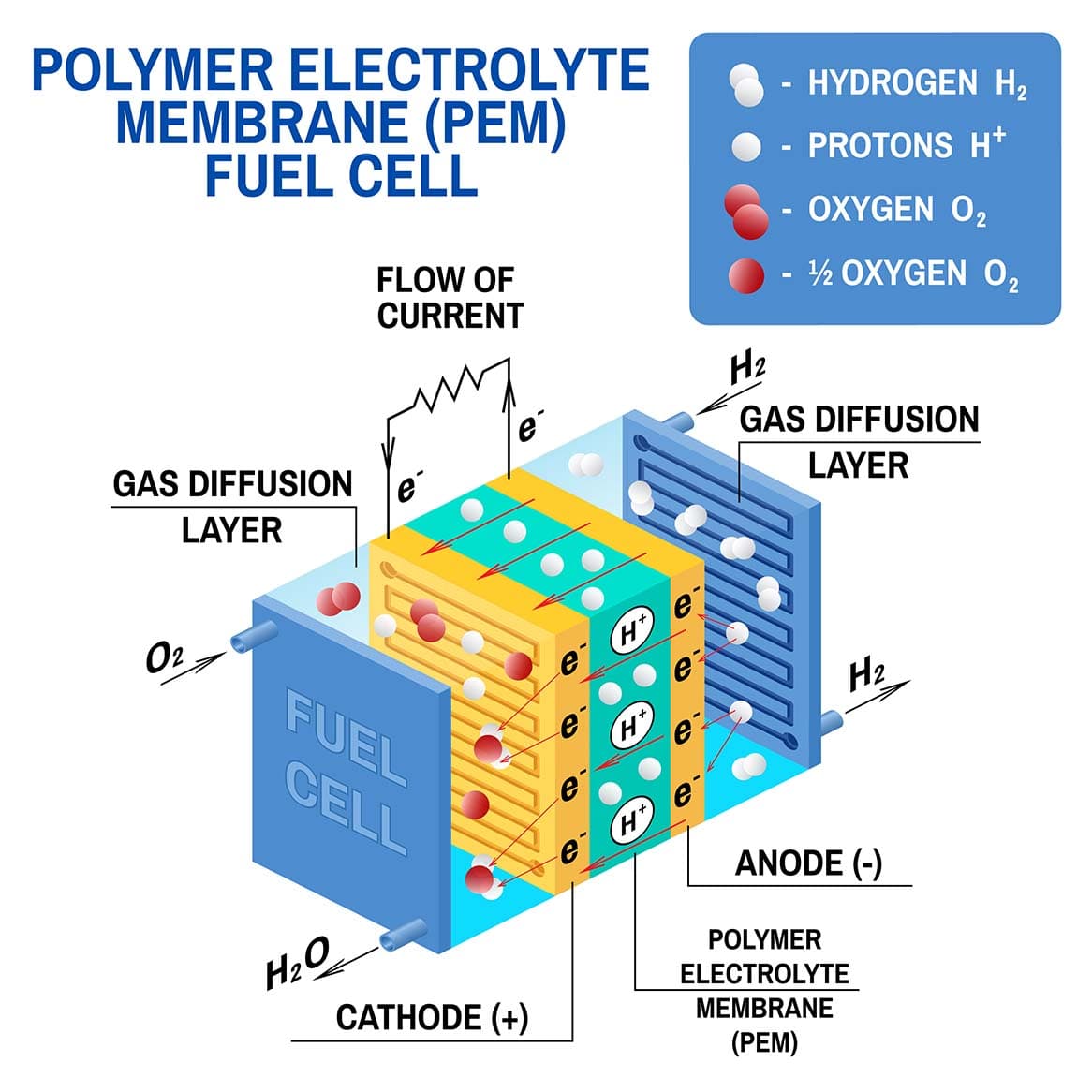

Proton Exchange Membrane Fuel Cell (PEMFC) Working Principle Diagram:

This type of fuel cell uses a proton exchange membrane as the electrolyte and operates at low temperatures (about 60-80°C). It features quick start-up, simple design, and adaptability, making it widely used in hydrogen vehicles, portable power generation devices, and household power generation equipment.

Sealless Magnetic Drive Pumps for Hydrogen Fuel Cells

During the process of generating current and water, fuel cells also produce heat. However, if the temperature of the fuel cell stack is too high, it will affect its operational efficiency. Therefore, a complete fuel cell system must have an efficient cooling system and heat recovery system to maintain a stable temperature range for the fuel cell stack.

In the cooling system, there is a flowing coolant to take away the waste heat, which needs to be safely pumped to circulate the coolant. For coolant circulation pumps, the PTCXPUMP Metallic Magnetic Drive Pump is ideal. Its leak-free design prevents coolant loss, and it offers high flow and high head specifications, making it the best pump for cooling systems.

PTCXPUMP Metallic Sealless Magnetic Drive Pump

Sealless structure, magnetic drive, no leakage concerns

The Power Generation Core of Hydrogen Vehicles: Fuel Cells

Fuel cells are the core power generation devices in hydrogen vehicle systems. Fuel cells can stably output electrical energy, ensuring the vehicle's range. Compared to traditional internal combustion engine vehicles, hydrogen fuel cell vehicles have zero exhaust emissions and higher operational efficiency, making them more environmentally friendly. The application of fuel cells is a significant contributor to achieving the zero-emission goal of hydrogen vehicles.

Advantages of Hydrogen Fuel Cells

- Instant Power Generation: Hydrogen fuel cells can generate electricity instantly as long as fuel (hydrogen and oxygen) is available, without the need for pre-charging like batteries.

- High Energy Density: Fuel cells have high energy density, providing more energy in a relatively small space.

- Environmental Friendly and Zero Pollution: Hydrogen fuel cells only emit water during operation, and are almost close to silent operation, producing no air or noise pollution, aligning with global energy-saving and carbon reduction trends.

Versatility and Prospects of Fuel Cell Applications

Besides their well-known application in hydrogen vehicles, fuel cells have various other common applications:

- Transportation: Buses, trains, ships, submarines, etc.

- Space Devices: Compared to traditional batteries, fuel cells provide higher energy density and produce drinkable water for astronauts, making them suitable for efficient resource use in space shuttles and stations with limited space.

- Backup Power: Fuel cells can serve as backup power sources for communication base stations, data centers, etc., providing immediate power backup in emergencies.

- Distributed Power: Fuel cells can be applied in disaster prevention microgrids in remote areas, energy storage systems for community housing, or in facilities such as traffic signals.

Currently, fuel cell technology for hydrogen fuel cell vehicles and other large-scale power generation equipment is gradually maturing. Commercial production indicates growing demand, and the future popularization of new energy is expected to improve air pollution and greenhouse effect issues.

Looking for a Sealless Magnetic Drive Pump Solution?

Choose the right sealless magnetic drive pump to make your system more efficient and safer!

- Eliminate leakage risk, and prevent coolant loss.

- Durable design, long service life, reduced maintenance costs.

- High-efficiency operation, energy cost savings.

- Smooth operation, low noise, no interference with the surrounding environment.

- Customization services available to precisely match your specific needs.

▌Read More:Top 5 Benefits of Using Metallic Magnetic Drive Pumps in Hydrogen Stations

E-fuel Production Application for Stainless Steel Magnetic Drive Pump

Pumps Application in Hydrogen Energy Industry