- Suitable for flue gas, VOC gas, condensation and heat exchange

- Unique gas diversion channel

- High heat exchange efficiency

- Small size

- Customization

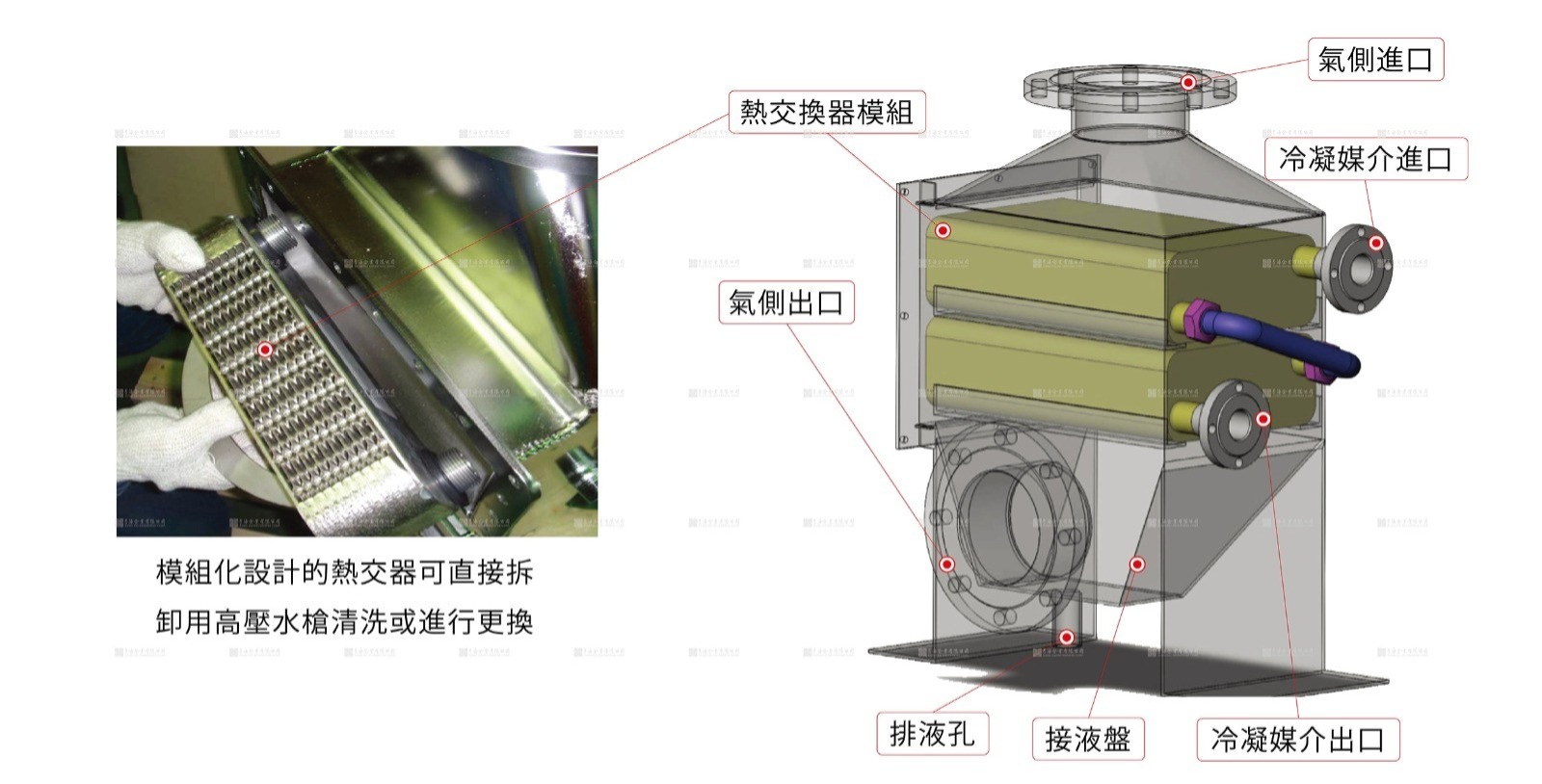

- Convenient maintenance and cleaning

- White smoke removal, waste heat recovery and reuse, solvent condensation recovery

- Features

- Performance Cases

- Specification

- Applications

COOL Plus VOCs Recovery Condenser

White smoke removal, waste heat, exhaust gas recovery and reuse, solvent condensation recovery...etc.Gas-liquid and steam-gas heat exchangers are suitable for use in various high-volume, low-pressure gas and organic solvent recovery processes.

- Small size, the same required energy volume is 3 to 5 times smaller than the shell and tube type.

- High heat transfer efficiency, and compared with the general shell-and-tube or fin type, the efficiency is 3 to 5 times higher.

- The pressure loss is small, and the pressure loss is only 5~10% of traditional fin heat exchangers.

- Patented distributor design and patented structural design improve the overall heat exchange efficiency.

- It is easy to maintain and can be cleaned directly with a high-pressure water gun or liquid immersion (CIP).

- Product applications, air condensation heaters, desulfurization post-processors, boiler exhaust gas recovery equipment, waste heat gas recovery, and corrosion gas prevention.

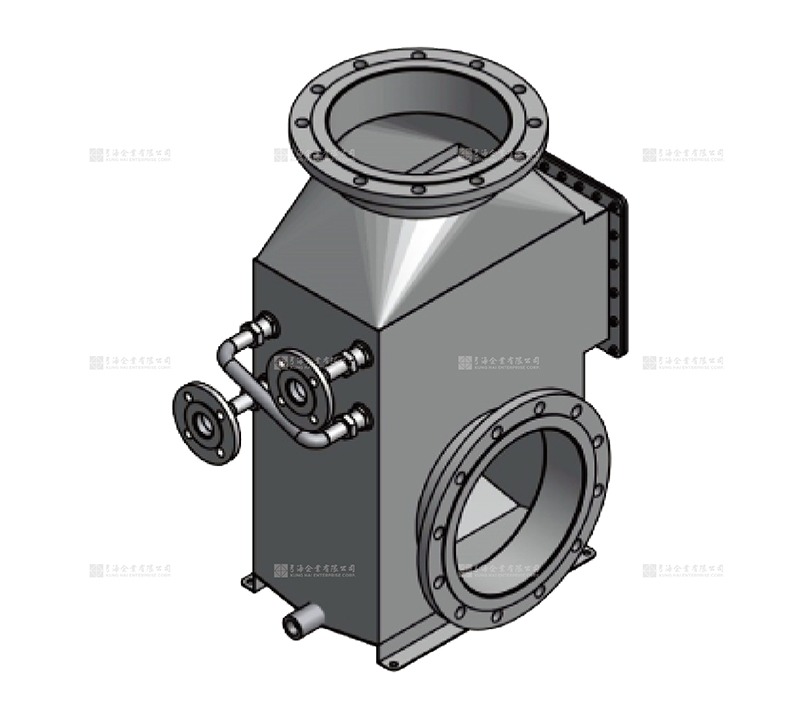

Top in and side out

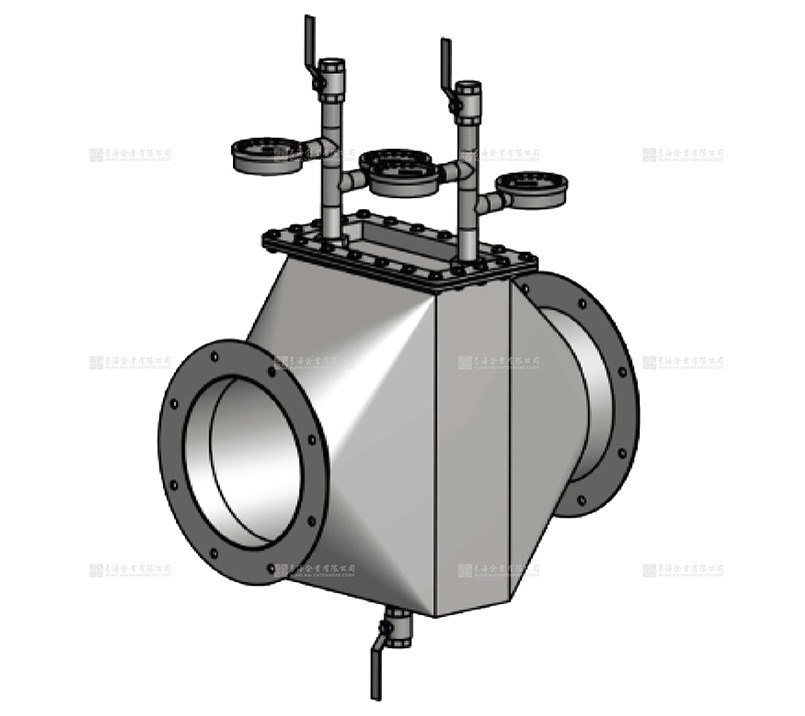

Side in and side out

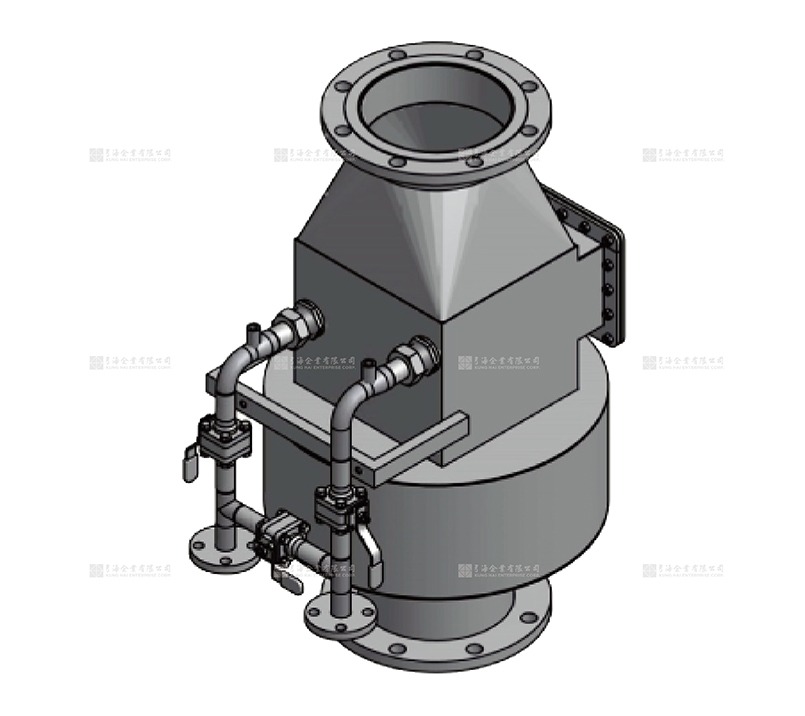

In and out

※This is a schematic diagram of the design. The product can be customized according to the user’s on-site space piping and conditions※

COOL Plus VOCs Recovery Condenser

ApplicationsProcess: Blower PP particle push

Content: The outlet temperature of the blower is about 50~60°C, so the PP particles may stick together due to heat.

Improve: Cool Plus uses ice water to lower the blower outlet temperature to 20~21°C, completely improving the situation of PP particles sticking into blocks.

Process: Blower (aeration tank, anaerobic sludge digester)

Content: Due to environmental protection regulations, the aeration tank must be covered. However, the outlet temperature of the blower reached 50~60°C, and the temperature was too high due to the cover, causing the death of bacteria in the aeration tank.

Improve: Through Cool Plus, the cooling water can be used to control the blower outlet temperature to about 35°C to improve the bacterial situation in the aeration tank and anaerobic sludge digester.

Process: Organic (VOCs) & Air

Content: As for cyclohexanone VOCs, we hope to achieve a catch-up rate of about 90%. The competitor in this case is Shell&Tube, but the effect can only reach 70% and requires a size of more than 2m.

Improve: Designed by Cool Plus, the device is smaller than Shell&Tube and can achieve a capture rate of 88%.

Process: Methanol VOCs tail gas condensation

Content: It is necessary to reduce the 50,000 ppm methanol exhaust gas to below 8,000 ppm. Previously, the shell and tube type was used, which had poor effect and was inconvenient in cleaning and maintenance.

Improve: The Cool Plus equipment has been online for more than a year now, and it can still be maintained at around 5-6000ppm, saving time and manpower investment in cleaning and maintenance.

Process: Boiler exhaust gas recovery and reuse and heat recovery process liquid heating

Content: The most important thing is to reduce the waste heat gas from the boiler from 150 degrees to about 70 degrees before it can enter the PP scrubber. Otherwise, the exhaust gas will be exceeded! But while cooling down, the process fluid is used as a coolant, effectively reusing waste heat.

| Proper temperature | Max 800°C |

| Plate material | 304 / 316L / 310 / SMO254 / C276 / Ni201 |

| Shell material | 304 / 316 / 310 |

| Maximum processing air volume | 50,000m³ |